Когда вы посещаете какой-либо веб-сайт, он может сохранять или извлекать информацию в вашем браузере, в основном в виде файлов cookie. Эта информация может касаться вас, ваших предпочтений или вашего устройства и в основном используется для того, чтобы сайт работал так, как вы ожидаете. Эта информация обычно не идентифицирует вас напрямую, но может дать вам более персонализированный опыт работы в Интернете.

Поскольку мы уважаем ваше право на неприкосновенность частной жизни, вы можете запретить использование некоторых типов файлов cookie. Однако блокировка некоторых типов файлов cookie может повлиять на ваш опыт использования сайта и услуг, которые мы можем предложить.

Вы разрешаете:

Строго необходимые файлы cookie (обязательно)

Эти файлы cookie необходимы вам для просмотра нашего веб-сайта и использования его основных услуг, и они не требуют вашего согласия. Эти файлы cookie позволяют нам предлагать вам основные функции веб-сайта (доступ к учетной записи, используемый язык, порядок воспроизведения, оплата). и т. д.), а также могут использоваться для проверки личности и обеспечения безопасности. Если вы отключите их, мы не сможем выполнить ваш основной запрос.

Статистические файлы cookie

Эти файлы cookie собирают анонимную информацию о ваших действиях в Интернете, что помогает нам улучшать структуру веб-сайта. Если вы отклоните эти файлы cookie, вы не сможете использовать определенные функции наших веб-сайтов и служб.

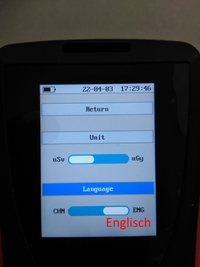

Файлы cookie предпочтений

Эти файлы cookie позволяют нам запоминать сделанный вами выбор в отношении ваших предпочтений, например, какой язык вы предпочитаете. Если вы отклоните эти файлы cookie, вы можете почувствовать, что эффективность просмотра веб-страниц снизилась.

Маркетинговые файлы cookie

Эти файлы cookie выполняют персонализированные действия для рекламы продуктов и услуг, которые вас интересуют. Если вы отклоните эти файлы cookie, вы все равно будете видеть рекламу, которая не очень соответствует вашим интересам или требованиям.